Post and Beam Straw Construction Technique

Straw has been used as a building material by many cultures for many centuries. In the Old Testament we read about the Israelites using straw and mud to construct monuments for the Egyptian rulers. Use of mud and straw mixtures to build walls is still prevalent in Africa, Middle East, Asia and China. Straw has been a standard material used for roofs by many cultures and even today in Ireland and Scandinavian countries one can see thatched roofs in rural areas.

The construction techniques described use straw as a filler in the wall sections. It further describes how one need not have to bale the straw to use it for wall construction. Straw-bale construction started at the turn of the century when John Deer invented a straw baling machine and the pioneers in the Northwestern part of Nebraska started to use straw bales as construction materials. Even today one can find houses built with straw bale and plastered with cement standing in Nebraska.

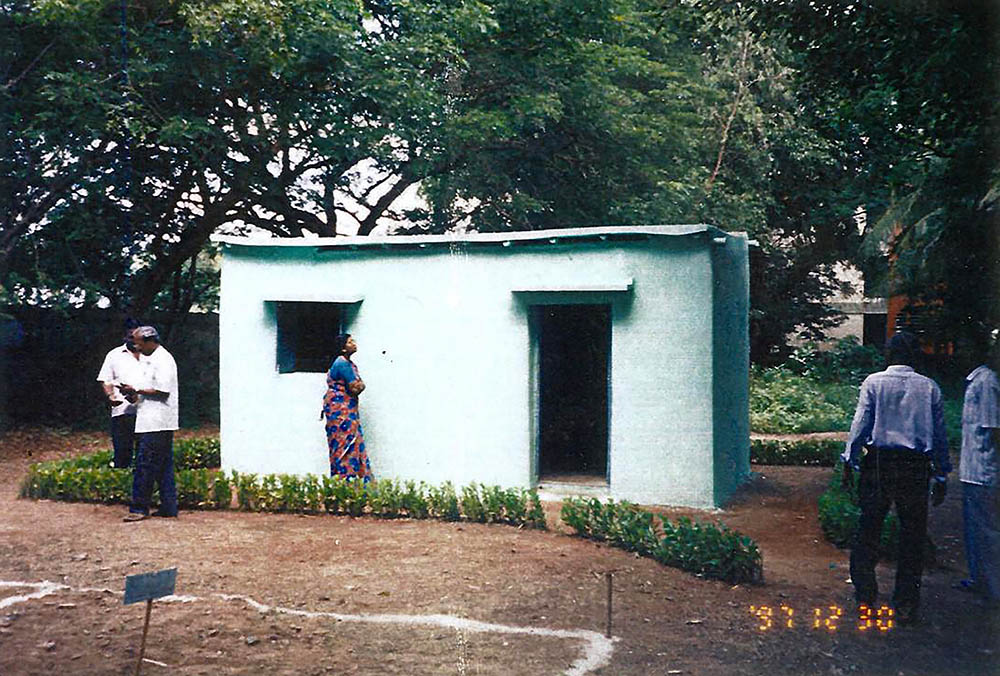

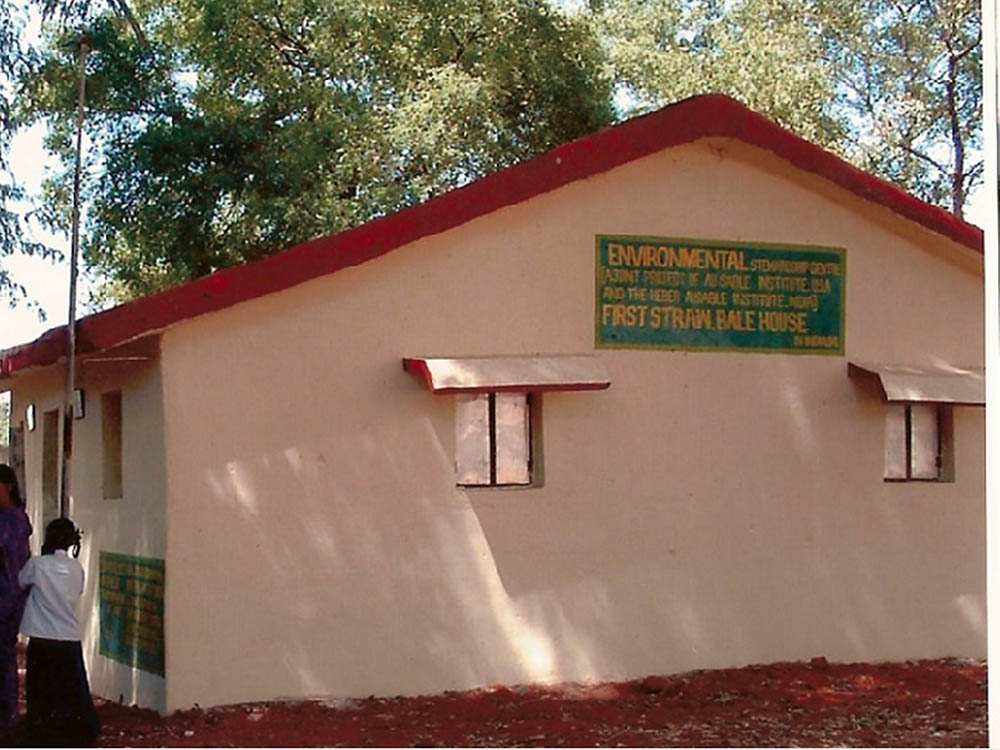

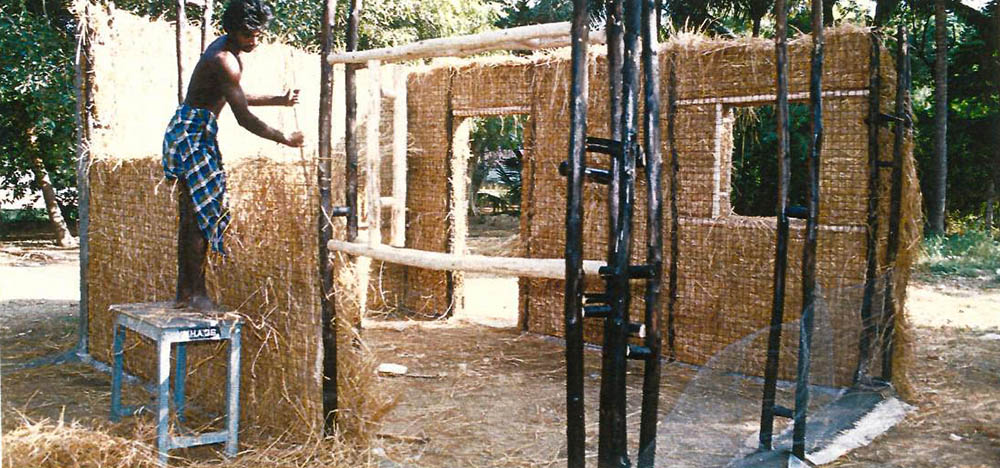

Using the techniques described, plastered straw structures were built in India and Pennsylvania. The pictures in the following pages should provide sufficient information for anyone to construct a low-cost, earth-friendly building using straw as building material for the walls.

One can find a number of web sites on the Internet that provide valuable information on owner built and conventionally built straw bale houses. These houses are found to be comfortable as they damp out noises and have a high R-value that far exceeds the code requirements. They are also safe as far as fire is concerned. Tests conducted by Underwriters Laboratory and other National Laboratories found the fire ratings of the plastered straw bale walls to be well above the requirements. There have been no reporting of termite infestation or other insect damages to the plastered straw bale walls.

We estimate that a plastered straw house in India costs one-fourth of the brick and mortar house and keeps the inside temperature 10 to 15 deg. F below the summer outside temperature. It was also noticed that these houses could be built with very little skill by the owners themselves and therefore, results in considerable savings in the owner builder.

Step 1. Lay the foundation for this building using standard methods. As the walls are not load bearing, a concrete foundation of 6 inches depth is sufficient. Dig at least 24 inches holes to set the treated poles and pour concrete for strength and stability.

Step 2. Build the frame work as shown in the photograph above. Fasten rigid fence material (not chicken wire) to the posts and create 9 inch to 12 inch cavities.

Step 3. Fill the cavities with straw or other waste materials like carpet padding, shredded paper, and styrofoam packaging materials.

Step 4. Plaster the inside and outside of the walls with mud dug from the foundation and let it dry for a couple of days.

Step 5. Plaster the walls with cement and sand mixture (1 part cement to 5 parts sand). Paint the walls with desired color paint.